In one of my recent posts, I defined what I called “the Intelligent Data Plane” and the SW components that exist within a data intelligent processing “stack” to make data produced within an enterprise “useful”. A company that has built a platform for collecting data from manufacturing facilities and presenting it to users in an intelligent way is Datanomix, Inc., a company located in Nashua, NH.

This platform is interesting because it fits into my thesis as a “Stage Two” platform where data is not only collected and presented to users intelligently, but where data is provided in a fashion that can aid other applications of interest to its users. In addition to performing its own analytic functions, this platform acquires, secures and generates data that can enable other analytic processes that may be of interest to manufacturers.

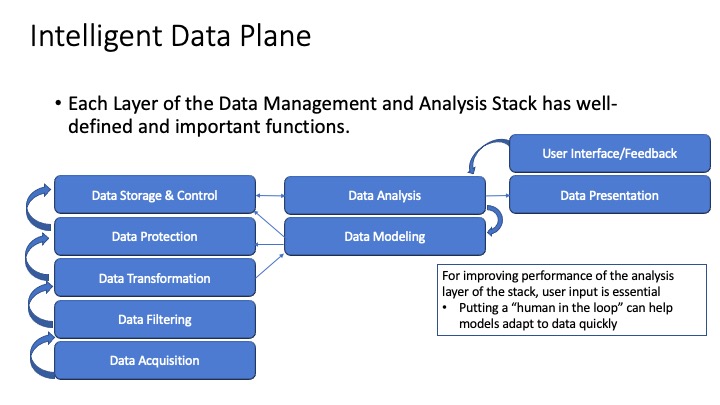

Please recall the diagram (below) for an overview of the intelligent data plane architecture.

Intelligent Data Plane (Manufacturing Data Analysis)

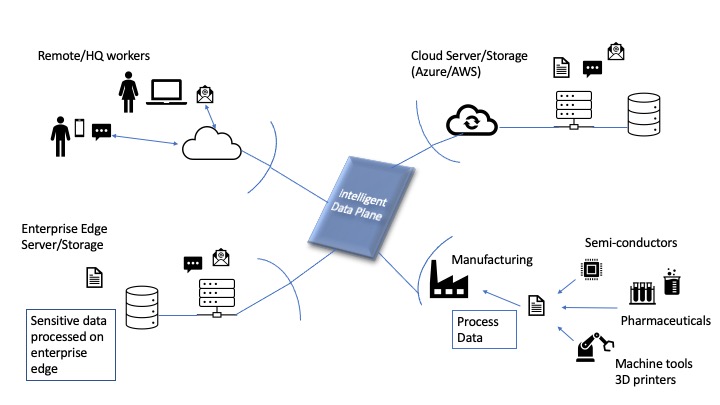

In this reference architecture for intelligent data analysis, Datanomix would be the Intelligent Data Plane component interfacing between the manufacturing factory floor and cloud services where vital production data is sent for analysis.

Datanomix Platform

Datanomix’ platform is an intelligent analytics platform that can access and collect production data from manufacturing machines (Computer Numerically Controlled “CNC” machines, “smart” lathes, 3 -D printers, etc.) over standard API interfaces. Datanomix deploys easily configured local SW components that interact with the factory floor machines to collect data from production equipment. The Datanomix SW intelligently acquires and filters the data into what is relevant to a particular process within the manufacturing workflow. Subsequently the data is transformed and transported to cloud SW components where it is saved, indexed for retrieval and formatted into reports that are meaningful.

The Datanomix SW transforms the data it retrieves into standard JSON objects that can be displayed in reports or indexed in the cloud. The objects are transported over an encrypted channel to the cloud data service (Azure for example) where it is indexed and analyzed. All data at rest is encrypted in the cloud for security purposes.

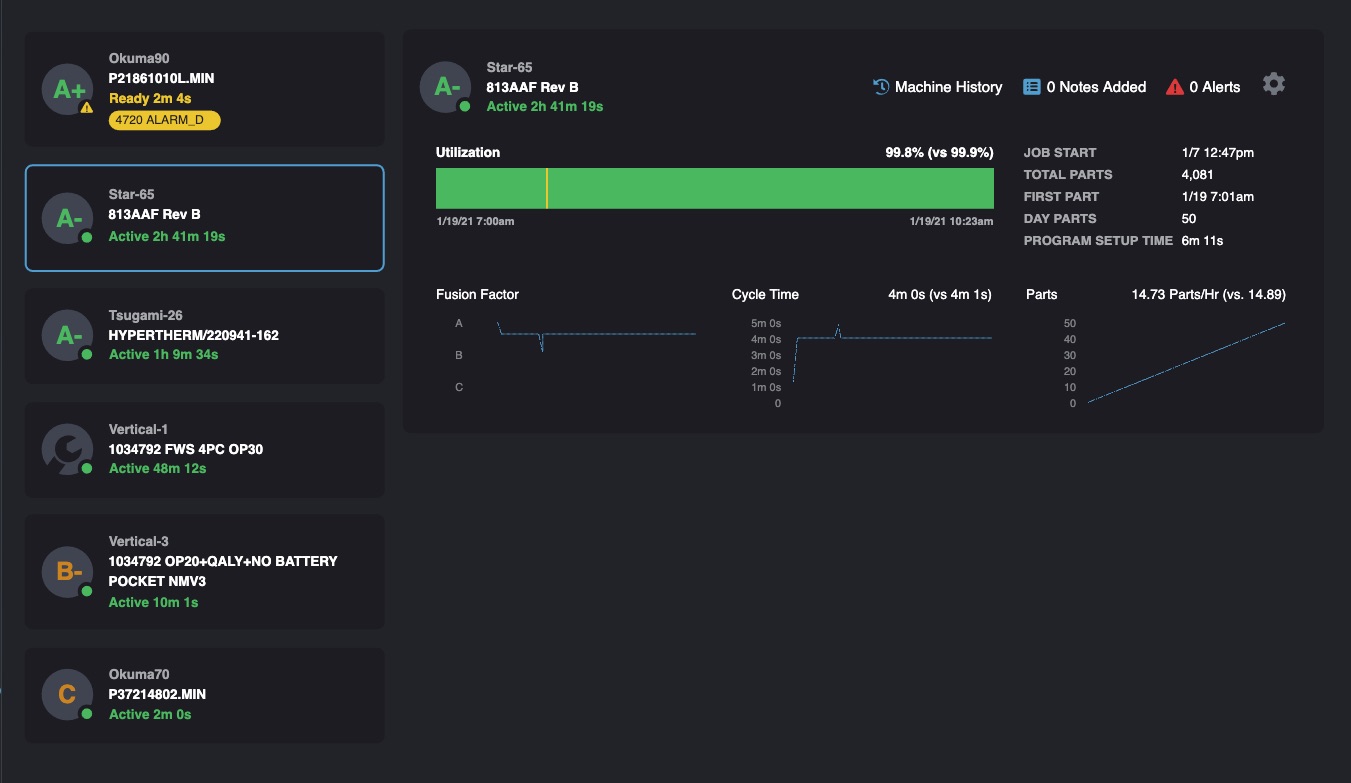

Production Monitoring Dashboard

The Datanomix SW also interfaces to standard ERP systems and can incorporate the company “GEMBA” board ( a Japanese term meaning “real place”) representing the status of the manufacturing process. It has standard connectors to display the GEMBA board on a Smart TV television monitor in a factory setting.

GEMBA Board

The Datanomix SW also has connectors for monitoring machine health and operating parameters. The SW can apply anomaly detection algorithms to establish automatic thresholds for normal operation and send alerts when a machine is operating outside of normal parameters.

By sending the local data to a hosted cloud service where it can be stored, indexed and analyzed, Datanomix can add features to the platform easily. Through their hosted cloud service they provide a wholistic view of an entire manufacturing process. Manufacturing managers get the data they need rapidly and conveniently to help them understand what parts of their operations may need refinement.

As data is stored securely and in a standard format understood by other applications, it can be shared easily. Datanomix’ customers may need to share process control data with their customers for quality assurance purposes. Due to these capabilities, Datanomix can provide true “Stage Two” capabilities by enabling data analysis, security and sharing without requiring a large commitment from their customer’s IT staff.

The platform is not limited to use by industrial manufacturing entities. The platform has relevant use cases with pharmaceutical manufacturers who collect large amounts of process control data and need to store and retrieve it conveniently. Use cases in the semi-conductor manufacturing space also exist.

Summary

Datanomix “checks the boxes” for intelligent data acquisition, filtering, transformation and secure transport of data to cloud locations (as shown in the Intelligent Data Plane architecture). Data at rest is protected within the cloud service with strong encryption as well. They have excellent User Interface capabilities to highlight the reports they can generate for customers. Analytic capabilities exist for monitoring machine performance. The platform is easily extensible in the future as more intelligent analysis features are requested by customers. In these respects, the Datanomix platform is a strong performer within the “Intelligent Data Plane” architecture.